Thermocol Mouldings

Thermocol Mouldings Specification

- Usage & Applications

- Architectural decoration, insulation panels, packaging, false ceiling, protective edges for fragile goods, wall and ceiling moldings

- Material

- Expanded Polystyrene (EPS) Thermocol

- Type

- Moulded sections, strips, corners, and customized profiles

- Grade

- Standard and Flame Retardant Grades available

- Heat Deflection Temperature

- Up to 70C

- Width

- Customized, typically 20 mm to 300 mm

- Length

- Customized, up to 2000 mm or as per requirement

- Thickness

- 10 mm to 50 mm (Customizable)

- Color

- White

- Shock Absorption

- Excellent cushioning for packaging usage

- Moisture Absorption

- Less than 1% by volume

- Surface Finish

- Smooth

- Installation

- Easy to cut and install using adhesives or mechanical fasteners

- Eco-Friendly

- 100% recyclable thermocol

Thermocol Mouldings Trade Information

- Minimum Order Quantity

- 100 Pieces

- Supply Ability

- 1000 Pieces Per Day

- Delivery Time

- 3 Days

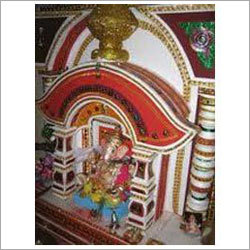

About Thermocol Mouldings

Assisted by a team of highly skilled professionals, we are manufacturing and supplying an exclusive range of Thermocol Mouldings. These mouldings are manufactured using corrugated sheets and advanced machines in accordance with the latest trends prevailing in the market. Provided mouldings have qualitative property of high shock absorbing capacity, that makes it highly suitable for packaging several fragile products. Our mouldings are offered in different prints, sizes, and colors as per customers need. We offer these Thermocol Mouldings to our valued clients at rock-bottom prices.

Features:

-

Water proof

-

Long operational life

-

Tear resistance

-

Eco- friendliness

Eco-Friendly and Durable Solution

These thermocol mouldings are manufactured from recyclable EPS, exhibiting a robust structure and minimal moisture uptakeless than 1%. Their smooth surface ensures a polished appearance, while available standard and flame retardant grades address diverse project needs across both decorative and protective segments.

Simple Installation with Custom Fit

Installation is straightforward, as the mouldings can be easily cut on-site and affixed using common adhesives or mechanical fasteners. With widths ranging from 20 mm to 300 mm and thicknesses between 10 mm to 50 mm, these mouldings offer great adaptability to any architectural or packaging application.

FAQs of Thermocol Mouldings:

Q: How are Thermocol Mouldings installed in various applications?

A: Thermocol Mouldings can be easily installed by cutting them to size using standard tools and securing them with adhesives or mechanical fasteners, making the process quick and straightforward for architectural, packaging, or insulation uses.Q: What makes these thermocol mouldings eco-friendly?

A: These mouldings are crafted from 100% recyclable EPS thermocol, ensuring minimal environmental impact while maintaining functionality and durability for a range of uses.Q: When is it recommended to use flame retardant grade thermocol mouldings?

A: Flame retardant grades are recommended when the application involves increased exposure to heat or fire risk, such as in insulation panels or false ceiling installations where fire safety standards must be met.Q: Where are thermocol mouldings commonly applied?

A: These mouldings are utilized in architectural decoration, insulation panels, packaging, protective edges for fragile products, and as wall or ceiling mouldings in both commercial and residential projects.Q: What is the process for customizing the dimensions of thermocol mouldings?

A: Manufacturers can tailor the width (20 mm300 mm), thickness (10 mm50 mm), and length (up to 2000 mm or customized) based on project requirements, ensuring a perfect fit for specialized architectural or packaging needs.Q: What are the benefits of using thermocol mouldings for packaging fragile items?

A: Their excellent shock absorption and cushioning properties protect goods from impacts and vibrations during transit, making them ideal for packaging delicate or valuable products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Molded Thermocol Box Category

Thermocol Office Interior Decor

Price 1 - 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Heat Deflection Temperature : Up to 70C

Material : Other, Expanded Polystyrene (Thermocol)

Color : White

Usage & Applications : Office interior decoration, wall panels, false ceilings, decorative partitions

Insulated Ice Boxes

Price 1 - 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Heat Deflection Temperature : 75C to 90C

Material : Other, High Grade Virgin Plastic with Polyurethane Foam Insulation

Color : Blue, Red, White (subject to availability)

Usage & Applications : Food storage, transportation of ice, vaccines, perishable goods

Decoration Thermocol

Price 1 - 100 INR / Piece

Minimum Order Quantity : 100 Pieces

Heat Deflection Temperature : Up to 70C

Material : Other, Thermocol (Expanded Polystyrene Foam)

Color : White

Usage & Applications : Decoration, Event Decoration, Craft Projects, Wedding and Party Decoration

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese